This is the Go Play 26BHS travel trailer. It uses the #1 selling floor plan across all brands of RVs in America.

We are offering this trailer for sale nationwide for $24,995. As of today, the average price of this same floor plan across all other manufacturers and brands is about $31,000 – $36,000. You are probably asking – Why is the Go Play so cheap!?

If you’re like most smart shoppers, you need to know how GO PLAY travel trailers can have such a cheap price without being cheap quality before you’re ready to decide if GO PLAY is right for you.

In this article I will share the 3 main ways we have brought the price of a GO PLAY down while maintaining its features and quality — and the things we’ve NOT done that could have reduced cost at the expense of quality.

I’ll explain the following in this article, click the link to jump ahead:

- Why Does GO PLAY Cost less?

- Is a Cheaper RV Always a Worse RV?

- How GO PLAY can be a High Quality RV Built for Less

- How We Reduced Cost of Labor

- How We Removed the Middleman

- Become a Knowledgeable RV Shopper

Why Does Go Play Cost Less?

There is a lot that goes into the cost of building quality RVs. At Bish’s, we are on a mission to create a line of RVs that boast industry leading price points without product compromise!

Most importantly – we are going to go to great lengths to help you understand the construction, feature load, and content of every Go Play so you can decide if the Go Play is right for you. What we really want is for you to be aware of what the Go Play has — and doesn’t have — up front.

We don’t want you to buy something only because you didn’t “notice” something was missing at the time you bought it. It is, after all, our goal to help you buy your 2nd RV the first time.

We are confident that we are bringing one of the most feature rich, conventionally built “stick & tin” RVs to the market – for well below market price – with GO PLAY RVs.

We have done this in 3 ways:

1. Reduced the overall Bill of Material costs or BOM without reducing the features in your trailer

2. Reduced the cost of labor or “direct labor costs per unit” by reducing the # of SKUs in production, building in “batch runs,” and committing to consistent builds at all times of the year

3. Reduced major overhead expenses in marketing, selling and spread fixed overhead expenses across more production to create significant competitive advantages.

Is a Cheaper RV Always a Worse RV?

Just because an RV costs less, doesn’t mean it’s built worse.

Several years ago, I was involved with the launch of a new RV brand. We debuted the RV to customers at an RV show in Louisville, Kentucky.

At the time, we had a special introductory price on the RV – we were asking $16,999. The RV was $3,000 less than any comparable RV on the market! We figured the doors would open, RVers would flock to us and we’d begin writing orders.

Who wouldn’t want to pay less for a great RV?!

To our surprise, when customers viewed the less-expensive RV, the overall response was not positive. Most customers were actually standoffish. They would quietly walk through the RV side eyeing it like it had moldy cheese hanging from the lights.

By midday I was shocked. We hadn’t sold a single one!

I was sitting on the sofa of the RV watching customers come in – and then right out – when a couple walked in the RV. After wandering through the RV for a couple minutes, the lady asked, “Why is this RV so cheap?”

That was when I realized, rather than flocking to the RV because of the low introductory price, the low price actually scared RVers because they were afraid it was too cheap.

This is completely understandable. We naturally equate value, build quality, and feature sets to price. With such a low price tag, it makes perfect sense to assume that the product has been cheapened to get to the price.

We’ve learned, however, that an RV does not have to be cheapened to get to a lower price! And we want to explain exactly how, so you can decide if GO PLAY has the quality you trust at a lower price.

High Quality RVs Built for Less

There are 3 main costs associated with building an RV of any kind. We call them The Big 3:

Bill of Materials, Cost of Labor, Operating and Overhead expense.

We’ve talked with many RV manufacturers to find the right partner who would let us work directly with them to help bring down the costs in each of these three areas so we could provide an RV option at the lowest price possible – without cutting features and content or build quality.

How We Reduced Bill of Materials Costs to Build GO PLAY

A bill of materials, or BOM, is every component and product put into an RV. This includes things like wood, aluminum, the frame, chassis, carpet, windows, appliances, furniture, etc.

The BOM for every floor plan is a little different because every RV floor plan is a little different. But, there are literally hundreds, if not thousands, of components that go into every travel trailer. And there are people within each manufacturer who can itemize an RV down to each bolt and nut!

We’ve put in time and research to find the two main ways money can be saved on the Bill of Materials.

1- We Could Reduce Features – But We Won’t

Deciding which features to put on an RV is a tedious process. A decision has to be made for each of the hundreds or thousands of components.

Let’s use the power vented fan in the bathroom, AKA the “Fart Fan,” as an example.

Should the fan be included? Consider the cost of the fan itself, the construction adjustments and time to properly frame it out, secure it in place and seal it up. It could cost as much as $100 just for that fan to exist!

A product team may wonder, “Will the customer even realize it’s there? Is it included in their buying decision?”

Adding a $100 cost on a trailer that a customer will pay $24,000 for? You may be thinking (and rightfully so), that’s nothing, of course a customer will like that. After all a $100 cost will add about $1 a month to the monthly payment.

The manufacturer looks at it a little differently, however. Remove that fan and, say, 10 other similarly small features – that adds up to $1,000 per trailer. Now times that by 5,000 RVs built and – bam – that’s a $5 million dollar savings.

This way of decreasing cost by reducing features is called “Decontenting” the RV.

Bish’s Doesn’t “Decontent“ Go Play RVs

“Decontenting” Is not a strategy we are using. Quite the opposite – our goal is to “feature load” these RVs at a lower price.

This does not mean that the GO PLAY includes every possible feature. We too have to make decisions – and we hope to hear from you. What features would you like to see? Which features do you think are a waste of money? Let us know at [email protected].

Okay – that’s a lot to say we really didn’t save any money by eliminating features. But GO PLAY costs less, so where did we save money on BOM costs?

2- Cutting Costs through Purchasing Strategies

We knew that “decontenting” wasn’t for us. But we WERE able to find savings using purchasing strategies.

When we stumbled onto this one we got a little excited.

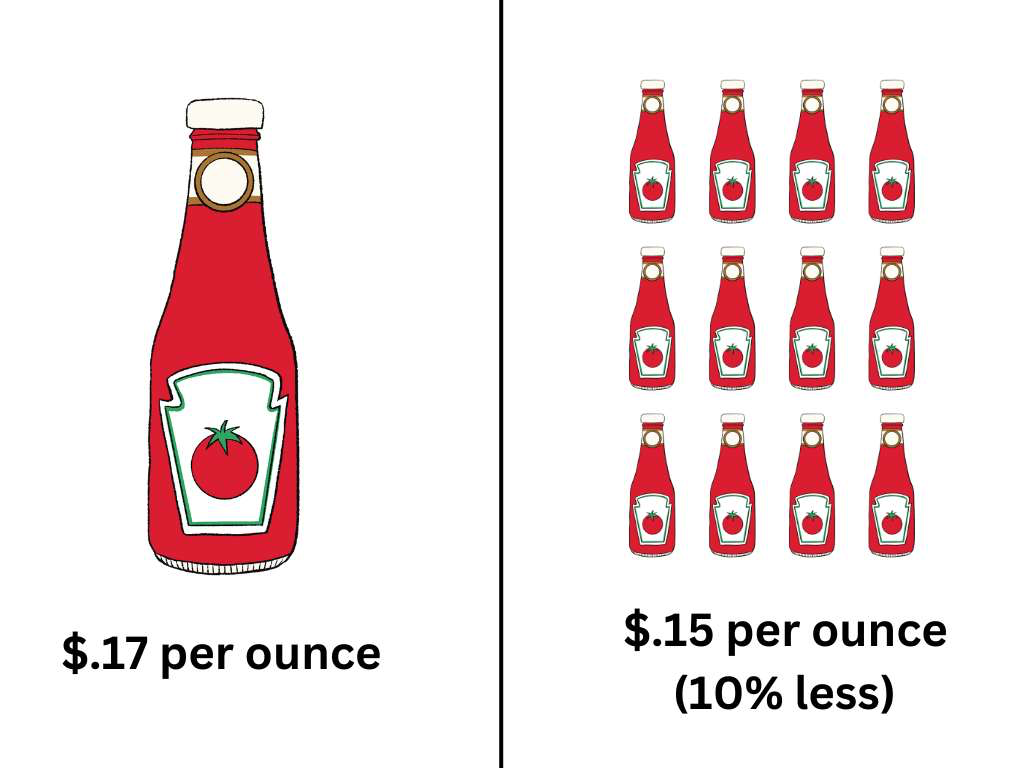

Say you’re going to sell some burgers. You go to the store to buy ketchup. You buy a 20 oz. bottle of Heinz Ketchup. Amazon sells this today for $3.48. But what happens if you try to buy an entire case of the same ketchup?

I found, the exact same ketchup, bottle and all, can be purchased by a retail customer as a case of 12 for .32 cents less a bottle.

Okay, so big whip, you can save a whopping .32 cents on a bottle? It sounds small, but it’s almost 10% less!

Now, when you compound things, saving up to 10% – or even more when you’re buying on a larger scale – the discounts can quickly add up to thousands of dollars!

Saving money this way spoke to us, and we knew it held the answer for how we could lower costs for the GO PLAY.

Here are 3 ways we’ve worked with the manufacturer to give them more purchasing leverage:

1- Every GO PLAY trailer floor plan is built the same way.

Everything you see on a GO PLAY is standard. Standardization helps ensure a standard BOM and expected quantities, as well as bulk buying power.

Eliminating variation allows the purchasing team to give exact expectations to the vendors. Vendors are then able to give commitment guarantees in their purchases. Certainty helps build trust and confidence with the vendors, which makes them more willing to reduce costs.

2- Committing to a certain number of RVs to be built in consistent runs over the year.

Consistency gives purchasers advance notice of when the RVs will be built and allows them to negotiate batch purchasing throughout the year. This helps keep their vendors’ production plans running consistently and smoothly.

This also allows the purchasing team at the manufacturer to go to bat with their vendors. If the furniture company we work with, for example, has less demand for production in the winter months, we will contract with them to have a portion of our product built during their slower months.

Our up-front commitment to purchase RVs throughout the year gives the manufacturer confidence that they can take advantage of a big discount by building extra furniture in the off-peak season.

3- Building 8 floor plans.

The number of floor plans you build increases component variety.

There is a lot of difference when you build a 21’ trailer vs. a 30’ trailer. The extra 9’ of trailer requires more wood, more aluminum, probably more windows, an extra sofa or chairs, etc.

We learned that you can reduce variation and save a lot of money by building fewer floor plans. (This also plays a big part in reducing labor costs – which we’ll get into below.)

This posed what we considered a significant challenge: How do we buy a limited number of floor plans AND buy in bulk? It took a lot of time to figure out – but over the past few years we’ve tried to study the market as in depth as we could, and we’ve learned something very interesting.

But, before we show you what we learned, we need to provide a little context.

The Go Play is built using conventional, or stick & tin, construction.

Conventional travel trailers are considered more of an entry-level RV, but not all stick & tin trailers are equal. Equipment, options, and quality can vary immensely.

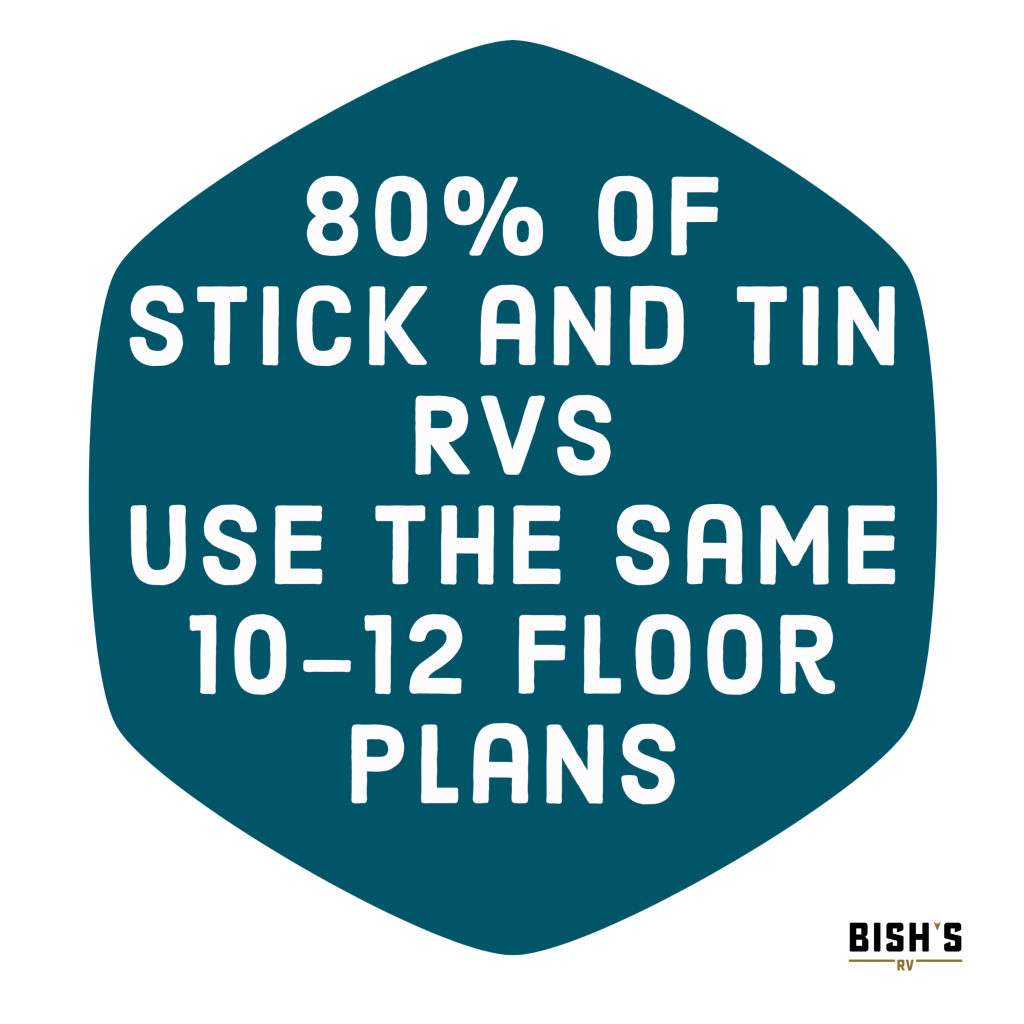

One thing is consistent – nearly every manufacturer builds the same core floor plans.

If you take the branding off the trailers you’d find that about 80% of all Stick & Tin RVs sold can be lumped into 10 – 12 floor plans.

To put that in perspective – there were around 35,000 new “Stick & Tin” RVs sold in the United States last year. 26,000 – 28,000 of those used the same 10 – 12 floor plans.

With this extra bit of knowledge, we chose to narrow our current floor plan selection down to 8 floor plans.

We realize that limiting our selection to 8 means that our current product won’t be right for as much as 30 – 40% of conventional “stick & tin” RV buyers. But, heck, if the floor plan match is close enough, you might see the value in saving some significant money with a slightly less ideal floor plan.

And if you fall into the 60 – 70% who are already going to buy these floor plans, dive into our product and feature videos so you can discover for yourself if the Go Play is right for you and your family.

How We Reduced Cost of Labor

The Cost of Labor is the cost of having an RV actually built. An RV is built on a big assembly line. It’s fascinating to watch these things start as a bare chassis on one end of the building and get pulled out the other side of the factory as a fully produced RV. All in the matter of a DAY!

Here’s what we learned about the direct cost of labor associated with building an RV and how we could bring down those costs.

When you consider the cost of people in a business, you recognize that these costs come from the number of people you have employed and how much you pay each of those people. The total of these two numbers equals your employee costs.

Employees x Pay = Employee Costs

Say you have 100 employees working in your plant to build trailers and each of them makes $35.00 an hour. In a standard 8 hour work day, you will pay $28,000 in production labor costs.

There is another piece to labor costs when you’re building an RV, and once we understood this, things got a little more interesting.

In production, you take the direct production labor and divide it by the number of RVs you are producing.

Production Labor ÷ RVs produced = Cost per RV

Say a factory can produce 10 RVs per day. If you take a labor force of 100 with a cost of $28,000 per day, that’s a total labor cost of $2,800 per RV.

We realized if we could figure out a way to use the same 100 people and produce 20 RVs a day, it would drop that cost per RV in HALF!

In manufacturing, this cost per RV is called the “direct labor cost per unit.” We saw this as a big opportunity to help the manufacturer lower the cost of labor per unit without reducing the quality or fit and finish of Go Play RVs.

Our challenge became: “How can we help our manufacturer partner produce more RVs per day with the same workforce?”

We learned that the manufacturer watches the “direct labor cost per unit” closely and they are always looking for ways to increase efficiency in their plant to help their people increase output.

Highland Ridge – the manufacturer we partner with – has a really cool culture and it was inspiring to see how innovative the line workers are themselves! After walking down their line and seeing the steps they’d taken to increase productivity – we were left scratching our heads.

How could we help? After all – we’re just RV people! We don’t know the ins and outs of manufacturing.

Ultimately, we asked the best experts we could find on the subject – the line workers themselves.

Here’s what the Highland Ridge line workers taught us:

1: The Number of SKUs matters!

In all the GO PLAY floor plans you will see that the standard items and features are the same. This has helped us reduce the number of unique SKUs making the build more consistent which helps our line workers get into routine and helps their production time go up!

Remember earlier how we mentioned that there are literally hundreds, if not thousands of components on each RV? Well – each unique component used in the build of an RV is labeled with an individual SKU Code. This is the same type of barcode that you scan on your groceries when you go through the self-checkout process.

The more SKUs or items that go into each RV build, the more complicated the build becomes and the longer it takes to get each RV from one end of the production line to the other.

Simply put—imagine we’re building a travel trailer and we want to reduce the time in production by reducing SKUs.

Now, let’s design this a little differently – let’s say we decided to remove the windows from this RV . Of course we never would—but we’ll pretend to illustrate what we learned from these line workers.

The process of installing a window begins while building the RV’s frame. Each window is framed in, then once the side wall aluminum skin is layered over the frame, a router is used to cut out the excess aluminum skin of each window area. A line worker will then secure and install each window into this preset frame down the line.

Each window must then be secured to the aluminum skin and all the edges sealed to ensure water won’t run into the trailer from the outside.

If you remove every window then all this labor time is saved and the RV can now move from one end of the line to the other faster.

Clearly, we wouldn’t remove windows from our RVs – that’s just crazy. I mean, sure, if you reduce items, features and content from an RV you could ultimately build a cheaper RV, but who wants an RV without windows?

At first glance, we didn’t see how we could help reduce the number of SKUs until we looked at it a different way. Keep in mind each UNIQUE component has its own SKU. Let’s throw those windows back on this RV:

Now notice the variation between the windows. We have 4 windows on this side of the RV alone. Notice how 3 of the windows are slightly different sizes. That means we have 4 windows but 3 different SKUs.

We realized we could use the same exact window size in as many of the spaces as we could to reduce the overall number of SKUs without compromising the features in your RV.

This not only helps with labor, but we can also get better bulk discounts when we can increase the quantity of any given SKU.

As you can see, the 4 different windows are now only 2 different windows.

We’ll use the same windows not only in the same trailer, but also on the other floor plans as well. Before there may have been up to 20 different windows/styles spread between the 8 different floor plans. We’re working to bring that number down to less than half that.

When we’re building 1,000 trailers streamlining products can save hundreds of hours in production.

Less variation even increases the build quality while it reduces cost! Workers can get used to installing the same size frames and do it quickly with fewer mistakes.

Of course this is not just windows, it can apply across any like items on the RV.

We’ve found the same approach applied to wiring, bolts and nuts, lighting fixtures, outlets, vents, switches, plumbing pipes and fixtures, wheels and tires, stoves, refrigerators, sinks, doors, roofing material, and paneling.

Now the second thing we learned from the line workers:

2- Changing up the floor plans or models decreases worker output.

Choosing to limit ourselves to 8 floor plans was the first step to create and sustain higher levels of output.

The average line builds as many as 15 – 30 different floor plans or models on a given day. These builds are usually based on the orders a manufacturer receives from any one of the 300 – 400 dealers they work with throughout America.

In plants across America – you’ll see each RV coming down the line and it will have a tag or sheet of paper indicating which floor plan and what options are to be built on that RV. It’s not uncommon to see as many as 3-5 different floor plans being built on the same RV line on the same day.

Switching from one task to another decreases line worker efficiency, because it takes time to adjust to the new task and get into the groove of the work.

It’s like cooking a meal. If you are cooking a series of dishes that have different ingredients and require different techniques, it can be challenging to switch between them seamlessly.

If you start out making a salad and then switch to making a stir-fry, for example, you’ll need to wash different utensils, chop different ingredients, and adjust to the different cooking times and techniques required for each dish.

Transitions make you less efficient as you adapt to the new task.

It takes time for the workers to adjust to the new requirements and workflows when an RV manufacturer switches from building one floor plan or model to another. They may need to adjust their tools and techniques for the new design.

These changes can result in a temporary efficiency decrease while workers adjust to the new requirements.

Our solution: Batch Runs

To improve efficiency we’ve committed to build our floor plans in what the manufacturer calls “batch runs.” This means that we run the same floor plans in packs of 50 – 100. For the factory this means that for at least one day – and sometimes many days – they are only working on the same floor plans.

Batch runs allow the line workers to get in the groove and stay in the groove for a sustained period. Not only does this help increase the output of trailers per day, but also has proven to increase the quality of the output!

3- Experienced Line Workers Make All the Difference

The last thing we found, and perhaps the most important of all, is the line workers themselves.

Experienced line workers are critical to the efficient output in an RV factory. Workers with experience and expertise perform their tasks quickly and accurately. They are familiar with the production process and the tools and equipment used. This allows them to work efficiently and effectively.

These highly skilled line workers also have specialized knowledge and techniques to work faster and produce higher quality products. They may have a deep understanding of the materials and components used in the RVs, allowing them to work with greater precision and accuracy.

While this is a work in progress, we’ve made commitments to the manufacturer to build a certain number of RVs each year. Because camping is seasonal, RV manufacturing has downtimes in the off season.

Helping our manufacturer produce during their off-season ensures production work for the line workers when they need it the most. This stability provides comfort to the workforce and helps our manufacturer retain their best line workers!

While this one is hard to measure – we are confident it is the secret sauce for sustained success and quality!

How We Removed the Middleman

The other costs of a manufacturing business – Overhead, Marketing, Sales Costs, Engineering. We refer to this as “removing the middleman”

Overhead or “Fixed” Costs

General operating and overhead expenses are a manufacturer’s expenses that are not directly associated with building each individual RV, but are necessary for the business to operate.

Every business has expenses. The cost of a facility, machinery, utilities etc. Many of these expenses are “fixed” expenses, meaning to matter what you do, how much you produce – the costs stay the same.

If you rent a building and the rent is $100,000 per month, it is always going to be $100,000 per month or $1,200,000 per year. If you are only using ½ of that facility or only getting ½ of the output you could get out of that building, it doesn’t change anything about the rent that you’re paying.

If a manufacturer paying this rent builds 2,000 RVs a year then $600 per RV produced and sold goes to paying for the rent of their facility.

We can spread that same expense across twice as many products sold and cut the expense per RV in half if we can help the manufacturer double the number of RVs they build each year. This concept holds true for each of the manufacturer’s “fixed” expenses.

We partnered with Highland Ridge RV because they had excess capacity in their plants both in Indiana and Idaho – which makes their product available to a nationwide network. They also agreed to look at these expenses as something they already had in place. This “incremental” business was a win for them, so they agreed to pass the lion’s share of these savings directly to the customer!

Manufacturer Reps

But it doesn’t end there. Here’s something you can recognize for yourself the next time you go to an RV show.

As you go to different displays there will be salespeople lining the walk paths of each dealership display, but you will also notice some people who are there working who are not members of the dealership’s sales team.

These folks are “manufacturer sales representatives.” They are incredibly valuable to us dealerships. Usually there are 10 – 15 manufacturer reps for an RV brand to help the manufacturer train and keep all the dealerships across the nation up to speed on their product year after year.

Again, manufacturers will have 200 – 400 dealers selling their RVs across the nation. Keeping up with that is a big task. While these reps are super valuable, they can also be a big expense. Besides salary and pay, these reps will spend as much as 3 weeks a month on the road – so much so many of them have to do “laundry” on the road because they don’t go home for extended periods of time.

Travel costs over the last year have gone up by as much as 48%. Reps have to take multiple plane flights a month at an average of $500 and spend up to 180 nights a year in a hotel at an average rate of $150 – $200 a night. Then factor in rental cars and food and entertainment costs as they host dealers regularly.

It’s very realistic that each manufacturer will spend over $100,000 per year on these costs alone. Times that by 10 – 15 reps and you are well over $1,000,000 in expenses. Now add in their salary and compensation. We’re talking about several millions of dollars that companies spend every year to have manufacturer reps spread across the country.

Marketing Expenses

RV Manufacturers also spend a considerable amount of time and money marketing their products. You’ve seen a lot of them – whether it’s ads on the internet, promotional items, branded sponsorships, brochures, and websites. All of these things can cost significant money.

As a strategy to make our product price more competitive, all the marketing for the GO PLAY is done by us. We are training our team of RV Outfitters with the product content we are publishing at the same time on the website for all of you to consume.

You can see, this is a huge area of our cost savings, but we need to stress that there is a giant risk to our strategy. Product Development for RVs happens rapidly – and manufacturer reps are incredibly valuable in Product Development.

The cost of an RV rep can easily pay for itself in product development and enhancement. This is where we are betting on YOU. You will notice in every video we post, that we will ask for your feedback. We don’t just want , we need product features and feedback so that our line of RVs will really be enhanced and even designed by consumer feedback!

So please feel free to share your thoughts – both good and bad. Let us know the truth and we WILL be responsive!

Send us a message at [email protected]

Become a Knowledgeable RV Shopper

Folks, at this point we hope you can accurately answer why the GO PLAY is so cheap! We are confident that we are bringing one of the most feature rich, value priced, conventionally built “stick & tin” RVs to the market. We have done it in 3 ways:

1. Reduced the overall Bill of Material Costs or BOM without reducing the content we put into the trailer.

2. Reduced the cost of Labor or “direct labor costs per unit” by reducing the # of SKUs in production, building in “Batch Runs” and committing to consistent builds at all times of the year.

3. Reduced major overhead expenses in marketing, selling and spread fixed overhead expenses across more production to create significant competitive advantages.

Don’t take our word for it – explore our content on the GO PLAY. You will not only learn a lot about our product, but you will also be learning how we shopped for an RV when we chose a manufacturing partner to build out this exclusive brand!

Whether the GO PLAY fits your family’s needs or not – our goal is to help you become a knowledgeable RV shopper no matter what you buy!

If you’ve learned GO PLAY has the quality and features you need at a price that can’t be beat, check out these campers:

Thanks for taking your time to be with us and Thanks for considering Go Play.

Happy Trails!

Todd Nuttall

President – Bish’s RV